What is Centrifugal Pump

Centrifugal pump is the centrifugal force by the impeller rotation to transport fluid pump. Before starting the pump, the pump shell and suction pipe must be filled with water. Then start the motor to make the pump shaft drives the impeller and the water to do high-speed rotation movement. Water does centrifugal movement and thrown to the outer edge of the Impeller, then flows into the pressurized water pipe of the pump by runner of the volute pump shell.

Centrifugal pumps have a wide range of applications for transferring fluids in industrial operations. Reliable and mechanically simple. Many chemical plants and refineries have hundreds of centrifugal water pumps of various sizes conveying sundry liquids and slurries. These vital workhorses are used for water, flammable liquids, acids, caustics, and most other fluids.

All the centrifugal pumps can serve well for the industries but can be involved in accidents even if they are correctly sized and specified, made of the correct materials, and properly installed. So it must be careful when operating.

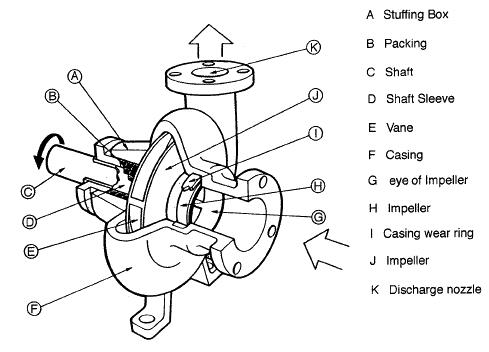

Centrifugal Pump Parts

The basic structure of the horizontal centrifugal pump is composed of an impeller, pump body, pump shaft, bearing, seal ring, stuffing box.

1. The impeller is the core part of the pump. Its high speed and high output, the impeller and the main role of the blade, the impeller before assembly through static balance experiment. The inner and outer surfaces of the impeller should be smooth to reduce the friction loss of the water flow.

2. The pump body is also known as the pump Shell, it is the main body of the pump. The utility model has the function of supporting and fixing and is connected with the bracket of the mounting bearing.

3. The role of the pump shaft is by coupling and motor connected to the motor, motor torque to the impeller, so it is the main part of the transmission of mechanical energy.

4. Sliding bearing is used as a transparent oil lubricant, oil to the oil level line. Too much oil to along the pump shaft seepage, too little bearing to overheat caused by the accident. In the process of pump operation bearing temperature in a maximum of 85 degrees, the general operation in about 60 degrees.

5. The sealing ring also is known as a leakage ring.

6. The stuffing box is mainly composed of stuffing, water seal ring, stuffing box, stuffing gland, and water seal pipe. The function of the stuffing box is mainly to close the pump shell and the gap between the pump shaft, do not let the flow of water in the pump to the outside and do not let the outside air into the pump. Always keep the vacuum in the pump. When the pump shaft and packing friction heat will depend on the water seal tube to a water seal ring to make packing cooling. Keep the pump running normally. In the running of the pump circuit inspection process of the stuffing, box inspection is particularly to pay attention. The packing must be replaced after 600 hours or so of operation.

Centrifugal Pumps Classifications

Centrifugal pumps with diffusion vanes are called diffusion pumps or, more recently, vertical turbine pumps

The centrifugal pumps can also be classified by the design of the impeller. Radial-flow impellers, axial-flow impellers, and mixed-flow impellers (both radial-flow and axial-flow).

Pump impellers are further classified as to the inlet flow arrangement such as single suction pump and double suction (which has a double inlet on each side of the impeller).

Impellers can be further classified with regard to their physical design: a closed impeller has shrouds or sidewalls enclosing the fluid flow, an open impeller has no shrouds or sidewalls, and a semiopen impeller is a mix of the closed and open design.

Another centrifugal pump classification is whether the pump is a single-stage pump (the pressure head is developed by a single impeller) or a multistage pump (the pressure head is developed by two or more impellers).

Centrifugal pumps can be further classified by physical design or axially split, radially split and whether the axis of rotation of the impeller(s) is vertical or horizontal. Horizontal pumps can be classified according to end suction, side suction, bottom suction, and top suction.

In applications, centrifugal pumps can be supplied with liquid via piping, or the pump may be submerged. Vertical pumps are called dry-pit or wet-pit types. The wet-pit pump (submerged) discharges up through a pipe system to some point above the pump.

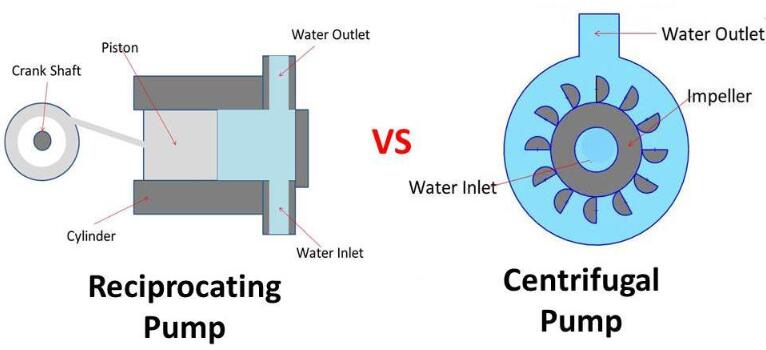

Centrifugal Pumps VS Reciprocating Pumps

Centrifugal and reciprocating pumps are used to pump liquids through a pipeline from an originating point to the delivery terminus at the required flow rate and pressure. To increase the flow rate, more pump pressure will be required. The majority of liquid pipelines use centrifugal pumps because of their flexibility and lower operating cost compared with reciprocating pumps.

Reciprocating pumps belong to the category of positive displacement (PD) pumps and are typically used for liquid injection lines in oil pipeline gathering systems.

A centrifugal pump increases the kinetic energy of a liquid because of centrifugal velocity from the rotation of the pump impeller. This kinetic energy is converted to pressure energy in the pump volute. The higher the impeller speed, the higher the pressure developed. Larger impeller diameter increases the velocity and hence the pressure generated by the pump. Compared with PD pumps, centrifugal pumps have a lower efficiency. However, centrifugal pumps can operate at higher speeds to generate higher flow rates and pressures. Centrifugal pumps also have lower maintenance requirements than PD pumps.

PD pumps, such as reciprocating pumps, operate by forcing a fixed volume of liquid from the inlet to the outlet of the pump. These pumps operate at lower speeds than centrifugal pumps. Reciprocating pumps cause intermittent flow. Rotary screw pumps and gear pumps are also PD pumps but operate continuously compared with reciprocating pumps.

Modern liquid pipelines are mostly designed with hydraulic centrifugal pumps because of their flexibility in volumes and pressures. In petroleum pipeline installations where liquid from a field gathering system is injected into the main pipeline, PD pumps may be used. Figures 11.5 and 11.6 show typical centrifugal pumps and reciprocating pumps used in the pipeline industry.

Centrifugal pump for sale JXSC centrifugal pump manufacturers provides all types of pumps.