What Is Pump Head & How to Improve The Lift of Slurry Pump?

What is the pump head?

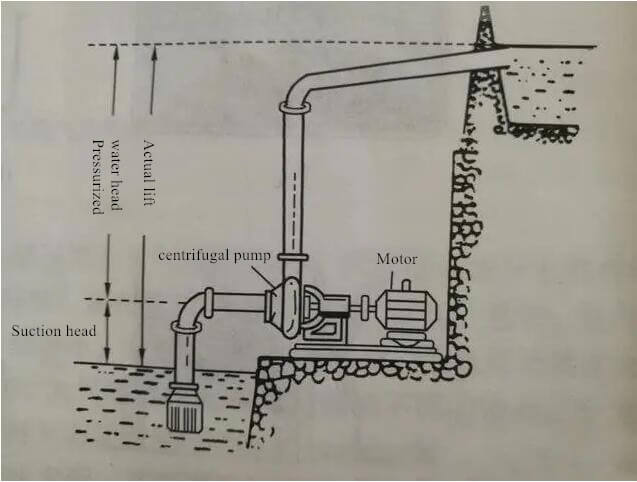

The pump head is the difference between the total energy per unit of liquid at the inlet and outlet sections of the pump. It is the height of the pumped unit liquid or the energy given by the pump. Also known as the head, lift of the pump, usually expressed by H, the pump head unit is the height of the liquid column of the pumped liquid, and the unit is m. H can also be expressed as the increase in the fluid’s pressure, kinetic, and potential energy head.

H=(p2-p1)/ρg+(v2²-v1²)/2g+z2-z1

In the formula

H——head, m;

p1, p2——the pressure of the liquid at the inlet and outlet of the pump, Pa;

v1, v2——the flow velocity of the fluid at the inlet and outlet of the pump, m/s;

z1, z2——the height of entrance and exit, m;

ρ——liquid density, kg/m³;

g – acceleration of gravity, m/s².

It can also understand the lift of the pump in this way. The pump head is the height that the pump sends the water, that is, how strong the pump is. Of course, it can send the water to a higher place. Otherwise, the water will reach a shallow height. It is more intuitive to use our common residential buildings for water supply. Generally, high-rise residential buildings require secondary pressurized water to be sent to high-rise buildings, which is characteristic of the large lift of the pump. The high-rise residents cannot use water if the pump head is very low.

How to select the pump head?

The pump head refers to the required lift, not the water lift, which is particularly important for choosing a pump. The lift of the water pump is about 1.15~1.20 times the water lifting height. For example, the vertical height from a water source to the place where water is 20 meters, and the required lift is about 23 or 24 meters. The pump head on the nameplate should be close to the needed lift when selecting a pump. In this case, the pump is the most efficient and more economically. However, it is not necessarily required to be equal. Generally, as long as the deviation does not exceed 20%, the pump can work in a more energy-saving situation.

How to improve the lift of the slurry pump?

A slurry pump refers to a device that converts electrical energy into kinetic and potential energy of the medium by means of centrifugal force (the rotation of the pump’s impeller) to increase the energy of the solid and liquid mixed medium. Mainly used in water treatment, coal washing plants, ore dressing plants, non-ferrous metal smelting, steel mills, sand washing and sand pumping industries, water conservancy and municipal sewage, power plant desulfurization, dredging, petrochemicals, shield machines, pipe jacking machines, filter presses machine, cyclone, screening machine, and other industries.

As we all know, the slurry pump is an indispensable piece of equipment in the mineral processing industry, and its primary function is to provide power for pipeline transportation.

Due to the slurry pump’s unreasonable use or blind choice, the pump, the flow, and the head of the pump cannot fully meet their actual needs. As long as we choose and use the slurry pump correctly and reasonably according to our situation, we can ultimately use the slurry pump efficiently. The following briefly explains some methods to reasonably use the slurry pump to increase the flow head.

- Choose a slurry pump with a larger model

Many customers who often use slurry pumps generally respond that they should choose a pump with a larger size, which is very beneficial to the stable working efficiency and service life of the slurry pump. The maximum flow head of the slurry pump is large.

- Increase motor power

The kinetic energy of the slurry pump comes from the motor. When the motor speed increases, the speed of the slurry pump will increase. After the rate is increased, the kinetic energy of the slurry pump will increase, and the lift will be higher. However, it is necessary to increase the head after scientific testing. The blind increase may reduce the service life of the slurry pump.

- Increase the impeller diameter

The larger the diameter of the impeller of the slurry pump, the greater the force on the slurry, so the pumped head will become higher. Still, it must confirm the replacement of the impeller with the Liangshan slurry pump manufacturer. Otherwise, it may reduce the slurry pump’s service life or damage it immediately!

How to improve the head of submersible slurry pump?

In the process of using the submersible slurry pump, the submersible slurry pump will have the fault of low pump head. What is the reason for the low head of the submersible slurry pump? How to solve it? Let’s take a look!

Reasons for low pump head

- Suction pipeline system intake air;

- The suction line or impeller is blocked;

- The inlet valve of the submersible slurry pump is not deployed or the valve is damaged, causing pump cavitation;

- The pump head of the submersible slurry pump is lower than the actual head of the pipeline, resulting in a small pump flow;

- The NPSH of the pipeline is less than the required NPSH of the submersible slurry pump, resulting in a small pump volume;

- The slurry concentration is too high.

Solution for the low head of the submersible slurry pump

- Exclude the cause of intake air;

- Reduce the slurry concentration of the submersible slurry pump or replace the pump with a larger diameter;

- Expand the inlet valve or replace the new valve;

- Improve the head of the submersible slurry pump;

- Eliminate blockage;

- Build a pipeline device so that the NPSH of the pipeline is greater than the required NPSH of the pump or replace the pump whose cavitation performance meets the requirements of the pipeline device.

When choosing pumps, many customers think that the lower the pumping head, the smaller the motor load. Misled by this wrong understanding, they select a very high pump head when purchasing a pump. In fact, for centrifugal pumps, when the pump model is determined, the power consumption is proportional to the actual flow of the pump. The flow of the pump will decrease with the increase of the head, so the higher the head, the smaller the flow, and the smaller the power consumption. On the contrary, the lower the lift, the greater the flow, and the greater the power consumed. In case of motor overload and heating, the motor may be burned in serious cases.