Application of Gravel Pump In The Ore-Dressing Plant

The application of gravel pump is use the gravel pump to transport medium such as ore pulp. The pump transports various concentrations of the iron ore pulp in the mineral processing plant. Therefore, the pump needs have the properties of corrosion resistance, abrasion resistance, non-blocking, easy to repair and replacement of shaft seal parts. Because the working environment is bad, if the pump parts without the properties, it may cause a slurry pump to wear out serious, low reliability and high power consumption.

Walker slurry pump is a new type of high-efficiency energy-saving products. The structure and hydraulic design of a series of the gravel pump are reasonable. The flow parts using high-hard alloy cast iron or rubber manufacturing. The sealed form may use the packing according to the different user requests. The auxiliary impeller uses the mechanical seal or the compound seal.

Our pump has the advantages of reasonable structure, high efficiency, lightweight, reliable operation, long service life, low noise, and convenient installation and maintenance. Its comprehensive performance is good, widely used to transport slurry containing solid particles in industries of metallurgy, power, coal, etc. The largest slurry weight that can transport: Ash Slurry and coal slurry accounted for 45% of the total weight, slurry or heavy media accounted for 60%.

Features

1. Wear-resistant, general normal use, 3 months to change the impeller (Manganese Steel).

2. Good maintainability, spare parts standardization, and easy to replace.

3. The head and flow rate suitable for the dressing plant.

How to choose the right pump

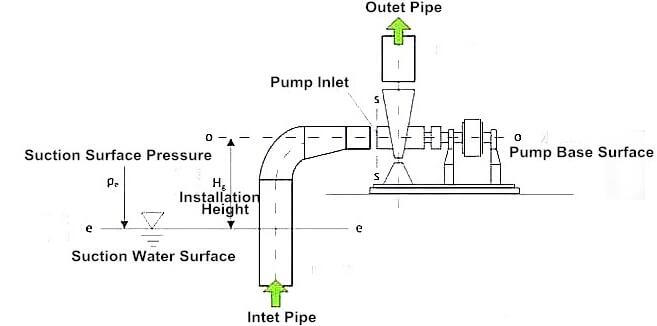

The efficiency and service life of the gravel pump determine the production cost and efficiency. If choose the right pump, the service life and production efficiency can be greatly increased. Selection of pump mainly includes a collection of known parameters, determination of pipe diameter and calculation of pump. We need to know the data what transport pipeline length L, transport pulp flow Q, pump needed to lift the height difference of H1, the process required for the remaining lift

H2. The transportation ore pulp’ density δ and solid-to-liquid ration.

Determine pipe diameter

According to the Formula Q=πd2v/4 to determine the diameter of the pipe, v represents the flow rate, Q represents the flow.

Calculation of slurry pump

Gravel slurry pump manufacturers Walker provides the lift H and flow Q. In general, they are the lift and flow of water, so it needs to be converted into the head and flow of water to calculate. Q=Q′(1+n),H=H′δ=δ(((λL/d+Σζi)v2)/2g+H1+H2 ).

In the formula, v is the velocity of the slurry in the pipeline. λ is the resistance coefficient along the pipeline. ζi is the resistance coefficient in the pipeline,m/s2. G is the gravitational acceleration. Finally, according to the characteristic curve of the combined pump of the clear water head and the clear water flow, the suitable type of pump is selected.

Gravel Slurry Maintenance

The whole machine of Walkerpump has been adjusted before leaving the factory. The unused pump doesn’t need too overhaul within 6 months after purchase. Only check whether the rotation is flexible, rust and oil can be used before filling. Other common maintenance methods are as follows:

(1) Keep the equipment clean, dry, oil-free and non-leakage.

(2) Whether the oil level in the check bracket is qualified or not, the correct oil level shall be near the oil level line and shall not exceed 2 mm.

(3) Check whether the pump is running with abnormal sound, vibration and leakage, and deal with the problem in time.

(4) Forbid the gravel pump working in the vacuum state. Because the pump not only acute vibration but also affects life in the vacuum state working. It must pay special attention.

(5) It should open the shaft seal water and cooling water before starting the pump. Then start the pump. after stopping the pump, after 15 minutes can close the shaft seal water and cooling water.