Types of Mining Pumps

There are many types of pumps, such as water pumps, mining pumps, industrial pump. This article will assist you to know Types of mining pumps. Ore Mining Pumps are the types of mining pumps which in the ore mining process. The mining water pumps depend on the fluid transfer and application need can divide into the slurry pump, gravel pump, dredge pump, submersible slurry pump, vertical slurry pump, horizontal pump, centrifugal pump, froth slurry pump, etc.

Mining pumps work for mineral processing, slurry transfer, abrasive sludge dewatering, acid and chemical reagent dosing, water supply and boosting, and wastewater and tailing transfer.

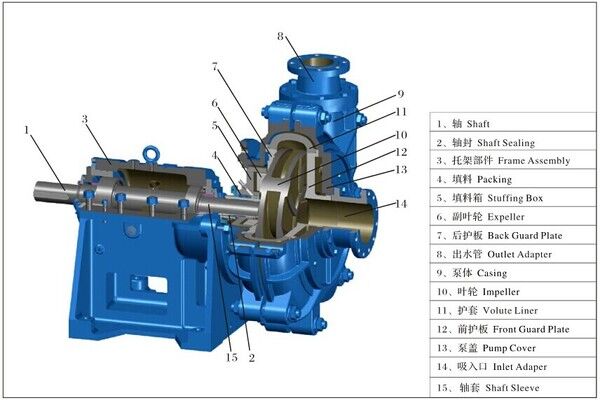

Slurry Pump

A slurry pump is a type of pump designed for pumping liquid containing solid particles. Slurry pumps changes in design and construction to adjust to multiple type of slurry which varies in a concentration of solids, size of solid particles, the shape of solid particles, and composition of the solution. Slurry pump is more robust than liquid pumps; they have added sacrificial material and replaceable wear parts to withstand wear due to abrasion.

Both centrifugal and positive displacement pumps can be used for slurry. Centrifugal slurry pumps can have between bearing-supported shafts with split casing or rubber- or metal-lined casing. Configurations include horizontal, vertical suspended and submersible.

Gravel Pump

Sand pump is most commonly used in the pumping system that move sand deposits to long distance. It is simply classified as sand pump, slurry pump and gravel pump. They are widely used in mining, metallurgy, coal washing, power plants, sewage water treatment, dredging, and chemical and petroleum industries.

Dredge Pump

Dredge pumps are a special category of heavy-duty slurry pumps that are utilized in the process of dredging. Dredging is referred to as the process of transport of underwater sediments (usually sand, gravel or rocks) from one region to another. Dredging takes place in shallow water areas of lakes, rivers or ocean for the purpose of land reclamation, desilting, flood prevention, creation of new ports or expansion of existing ports. Hence, various industries which utilize dredge pumps are construction industry, mining industry, coal industry and oil & gas industry.

Submersible Slurry Pump

Submersible pump is a device which has a hermetically sealed motor close-coupled to the pump body. The whole assembly is submerged in the fluid to be pumped. The main advantage of this type of pump is that it prevents pump cavitation, a problem associated with a high elevation difference between pump and the fluid surface. Submersible pumps push fluid to the surface as opposed to jet pumps which create a vacuum & rely upon atmospheric pressure. Submersibles are more efficient than jet pumps.

Vertical Slurry Pump

Vertical centrifugal pumps are also called as cantilever pumps. These pumps use an exclusive shaft & maintain design that permits the volume to fall within the pit as the bearings are external to the pit. This mode of pump utilizes no filling container to cover the shaft however in its place uses a throttle bushing. A parts washer is the common application of this kind of pump.

Horizontal Pump

These types of pumps include a minimum of two otherwise more impellers. These pumps are utilized in pumping services. Every stage is fundamentally a divide pump.

All the phases are in a similar shelter & mounted on a similar shaft. On a solo horizontal shaft, a minimum of eight otherwise additional stages can be mounted. Every stage enhances the head by around an equal amount. Multi-stage pumps can also be single otherwise double suction on the first impeller. All kinds of pumps have been providing as well as servicing this type of centrifugal pump.

Froth Slurry Pump

Mineral processing often relies on the formation of froth to separate rich minerals from gangue. In the process, chemicals are added and air. The rich minerals entrap the air and move as bubbles to the top of a flotation cell while the sand and clays of no commercial values sink to the bottom to form tailings. The whole process may be done in tanks in series called roughers, scavengers and cleaners.

Water Pump

Water pumps are simple devices. They force coolant through the engine block, hoses and radiator to remove the heat the engine produces. It is most commonly driven off the crankshaft pulley or in some cases the pump is gear-driven off the crankshaft. The coolant trapped between the impeller blades is thrown outward from centrifugal force. A suction (vacuum) is created in the center area of the pump housing. Coolant is drawn from the radiator via the lower radiator hose into the water pump.

The coolant is then circulated through the engine where it picks up heat from the combustion process and then is sent back into the radiator where the heat is transferred to outside air. Warranty analysis reveals the most common causes of water pump failures are due to contaminated fluid, excessive vibration or unbalanced loads. Contaminated fluid can contain abrasive materials that cause premature failure of the water pump shaft seal. Vibration or unbalanced loads can include improperly torqued or loose mounting bolts, bent or distorted pulleys, bent, cracked or improperly mounted fan assembly, defective fan clutch (if applicable) or improperly torqued belts.

Water Pump divides into the single-stage pump, two-stage pump and multistage pump.

Centrifugal Pump

Centrifugal pumps are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exists.

Common uses include water, sewage, agriculture, petroleum and petrochemical pumping. Centrifugal pumps are often chosen for their high flow rate capabilities, abrasive solution compatibility, mixing potential, as well as their relatively simple engineering.[2] A centrifugal fan is commonly used to implement a vacuum cleaner. The reverse function of the centrifugal pump is a water turbine converting the potential energy of water pressure into mechanical rotational energy.