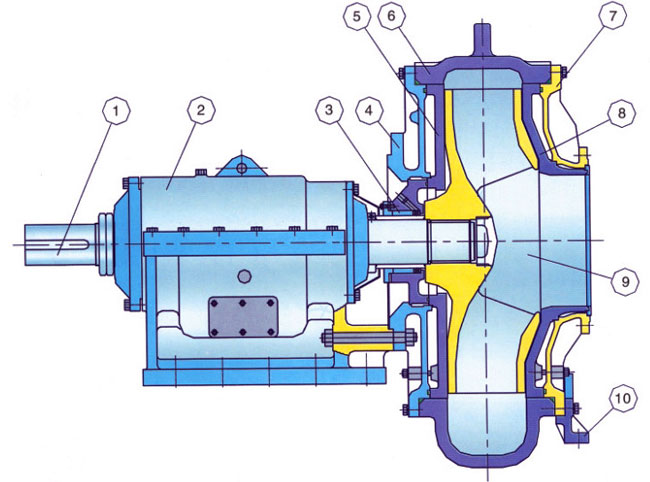

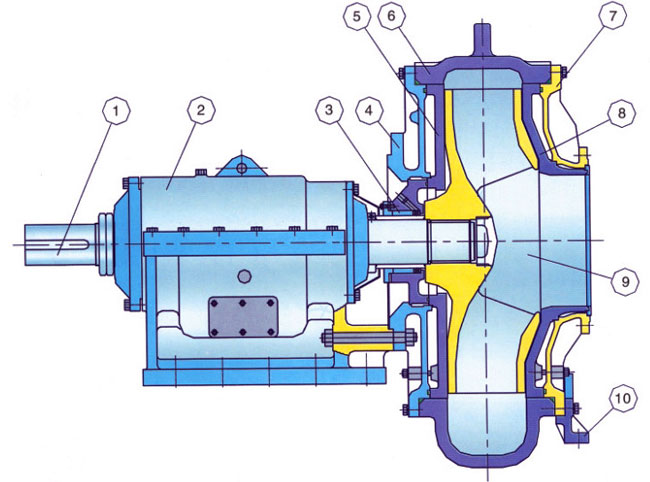

Construction of dredging pump

Main Part Number At The Drawing

1 – Shaft 2 – Frame 3 – Mechanical Seal Assembly 4 – Connecting Plate

5 – Rear Liner 6 – Pump Casing 7 – Cover Plate 8 – Front Liner

9 – Impeller 10– Support

>>>>Matel Pump Parts For Sale

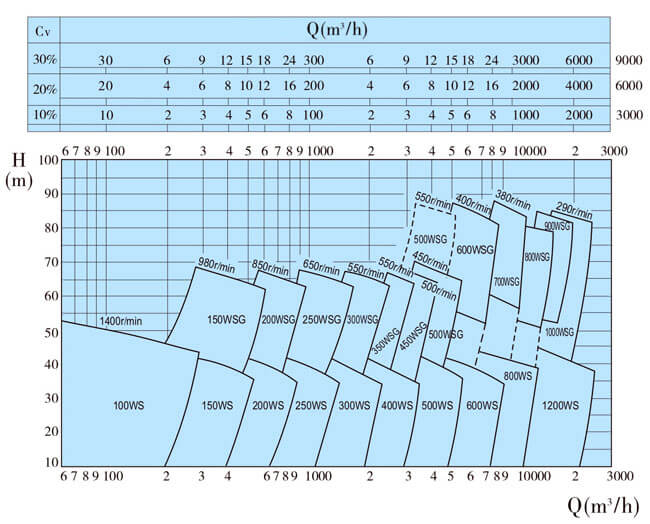

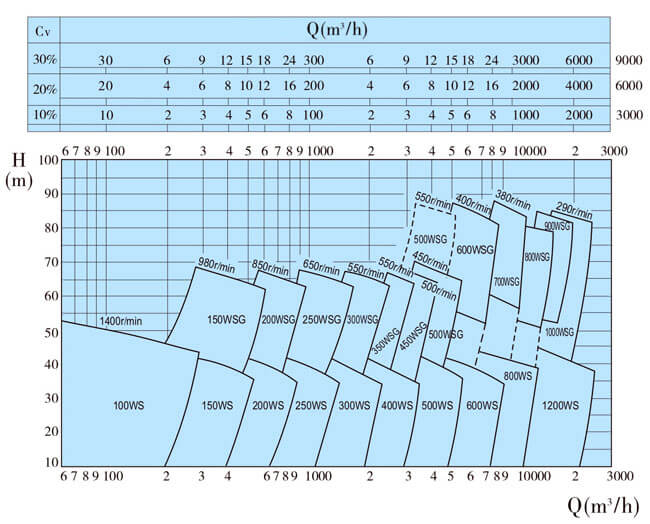

DREDGE PUMP SELECTION CHART

Note: Approximate Performance For Clear Water, To Be Used For Primary Selection Only.

WN500 Gold Dredge Pump is designed for continuously handling the most difficult higher abrasive slurries & sands which contain too big solids, It has advantages of single case, wide channel, high chrome wetted parts. The discharge can be installed in 360 degree in any direction, easy to install and use, good cavitation performance, anti-abrasion etc. WN500 gold dredge pump mainly used for dredging, explosive sludge, dredger, sewage, mineral processing and metal smelting slag etc.

√ Construction:

• preparation, pumping and recycling of bentonite

• transportation of mud, sand, and gravel

• pumping in depth and special foundations

• moving slurries in civil works

• emptying sludge for tunnel construction

√ Industry:

• pumping and recycling in cement mills and concrete factory

• sand and gravel winning in quarries

• pumping heavy/dirty water in mines(gold, diamonds, coal, copper…)

• extraction of very dense and abrasive liquids in mine (salt, uranium…)

• waste water treatment plant

• cleaning sand filters

• cleaning of sedimentation tanks

• pumping of scales, tar, oil residues, waste, tailings, lime in industry

√ Dredging:

• cleaning and dredging of marinas, harbors, dams, rivers, lakes, irrigation channels

• sand extraction

• marine salvage

• pipes and cables laying systems

• ship unloading

• high depth pumping works