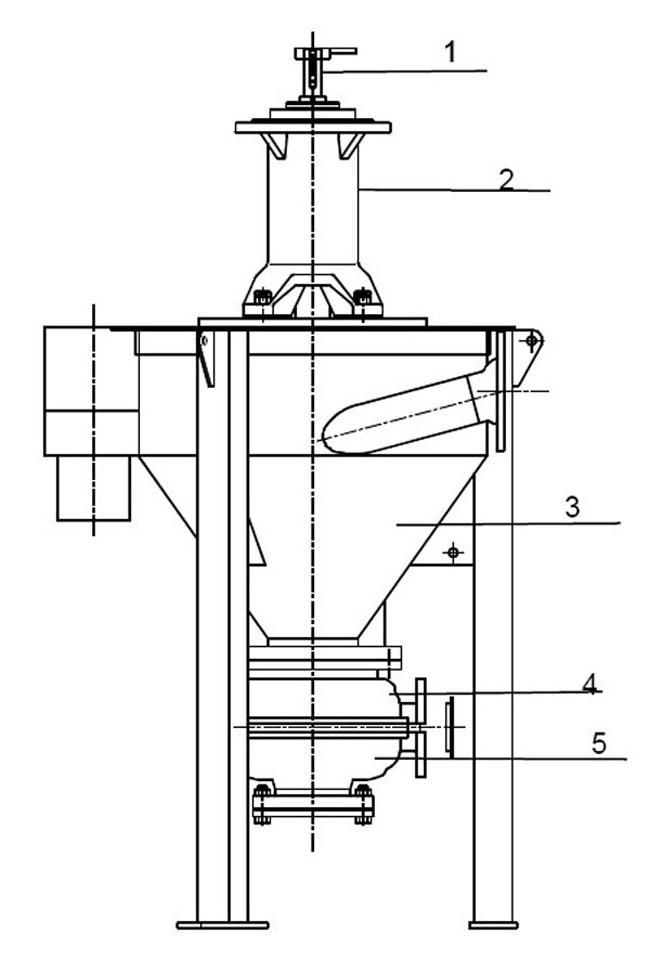

Construction of AF Forth Slurry Pump

Main Part Number At The Drawing

1. Bearing 2. Bearing Assembly 3. Tank 4. Frame Plate 5. Cover Plate

>>>>Matel Pump Parts For Sale

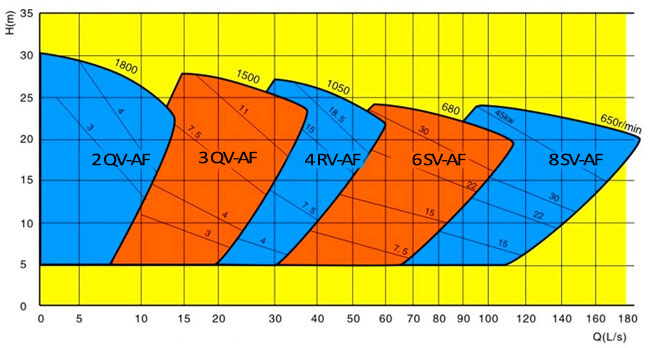

AF FROTH SLURRY PUMP SELECTION CHART

Note: Approximate Performance For Clear Water, To Be Used For Primary Selection Only.

√ Integrated unit for layout flexibility.

√ Smooth operation of the open vortex created in the sump and vertical “wet end” inlet prevents air locking.

√ Cantilever design does not require submerged bearings or shaft seals.

√ Bearing assembly with double protection sealing arrangement to prevent ingress of slurry.

√ Wear parts are available in a variety of different materials.

√ Simplified maintenance.

AFR Rubber Lined Vertical Froth Pumps are designed to increase the pumpability of corrosive frothy suspensions. The principle of operation is similar to that of hydro- cyclone separation. Air is separated from the corrosive slurry in a vortex created by the impeller rotation and the tangential inlet to the pump’s conical sump. This results in more efficient pumping at higher capacities and smooth operation, free from pulsations caused by air locking.

AFR series vertical forth pump is widely used in minerals froth handling processes, slurry transportation, coal, chemical, industrial applications. Especially for suitable for conveying abrasive & corrosive slurries containing foam.

Froth pump for sale, discuss with our engineer in detailed.