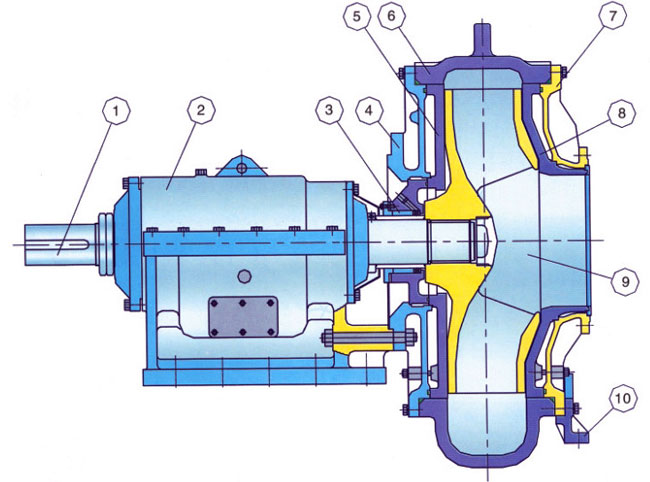

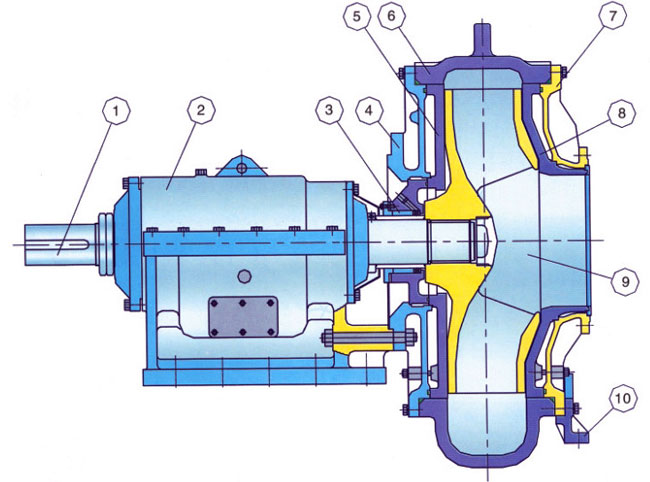

Construction of dredging pump

Main Part Number At The Drawing

1 – Shaft 2 – Frame 3 – Mechanical Seal Assembly 4 – Connecting Plate

5 – Rear Liner 6 – Pump Casing 7 – Cover Plate 8 – Front Liner

9 – Impeller 10– Support

>>>>Matel Pump Parts For Sale

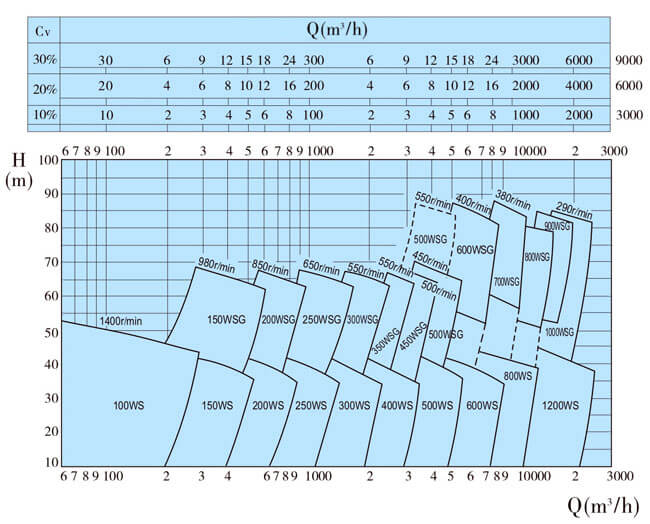

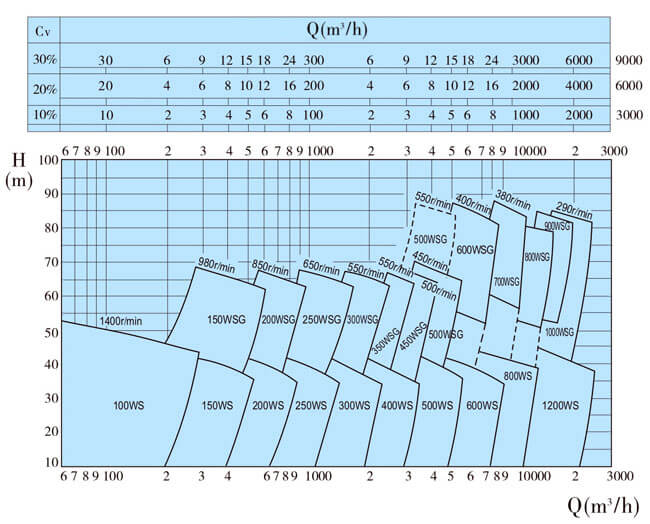

DREDGE PUMP SELECTION CHART

Note: Approximate Performance For Clear Water, To Be Used For Primary Selection Only.

√ Construction

• WN200 to WN500 dredge pumps are of single casing, single stage cantilevered horizontal centrifugal pumps. Two types of coupling with gear box: frame and pump box.

• WN600 to WN1000 dredge pumps are of double casings, single stage cantilevered centrifugal pumps.

• These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

√ Easy Uninstallation & Convenient Maintenance

• WN dredge pump is of front uninstallation construction to make uninstall easily and convenient

maintenance. And special tools are equipped for uninstalling the parts.

• Standard four-head trapezoid thread connection between impeller and shaft can transfer powerful torsion and be convenient to uninstall. Impeller uninstall ring at shaft sleeve side also make the impeller uninstallation much easier.

√ Good Performance

• Good NPSH can not only guarantee suction but also make deep dredge and high allowable suction density. Minimum NPSH: 4m.

• With wide impeller passage, pump can continuously pump gravel or high plastic clay without clogging. Max allow particle size: 350mm.

• Performance curves descend obviously to make pumps adopt pipeline distance changes.

• By changing the impeller diameter or impeller rotating speed, it can easily change the discharge with the same flow rate.

√ Material

• Material of wet parts is high wear resistant high chrome alloy.

• Considering the maintenance, wear resistant parts are nearly of the same wear life to reduce maintenance & interchange costs.

√ Low Hydraulic loss, High efficiency, Energy Saving

• Efficiency of WN is 2 or 3 percentage higher than other common pumps.

√ Reliable Shaft Seal, No leakage

• Shaft Seal types of WN200 to WN500: Mechanical seal, packing, or combination of mechanical and packing

• WN600 to WN1000 uses helical casing L rubber seal which is made of 3 pieces of L seal ring and one special thread shaft sleeve.

√ Turning

• WN700W to WN1000 can be equipped with turning to change rotating directions.

WN series dredge pumps are widely used for Dredging, Cutter Suction Dredger, Sand and Gravel, Contract Dredging, Tailings, Booster Pump, Sand waste pump, Material transfer pump etc.

PREV:WN300 Dredge Booster Pump

Walker dredge pump