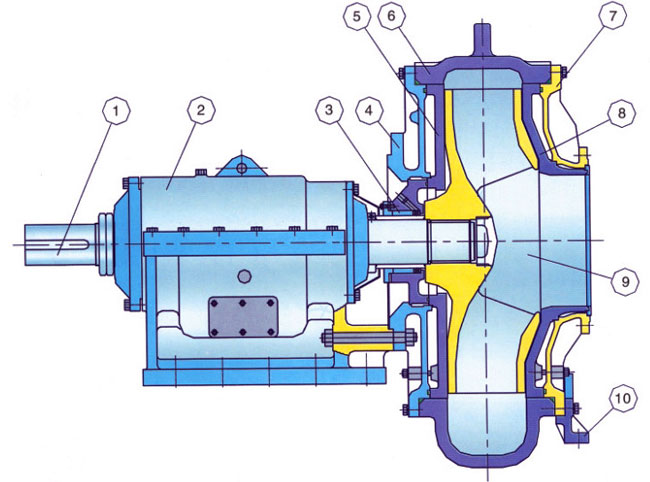

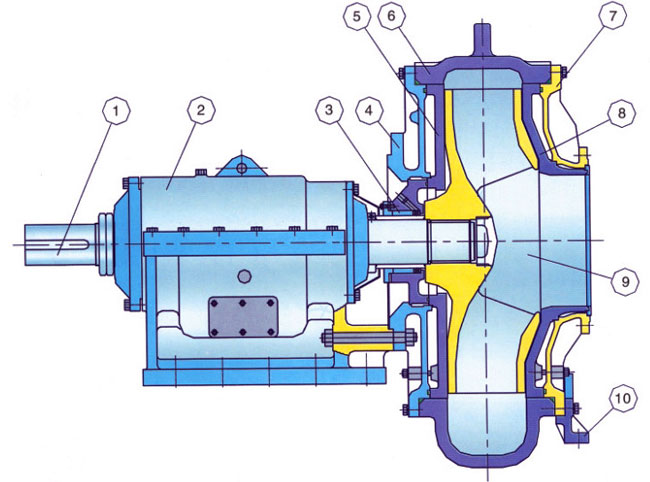

Construction of dredging pump

Main Part Number At The Drawing

1 – Shaft 2 – Frame 3 – Mechanical Seal Assembly 4 – Connecting Plate

5 – Rear Liner 6 – Pump Casing 7 – Cover Plate 8 – Front Liner

9 – Impeller 10– Support

>>>>Matel Pump Parts For Sale

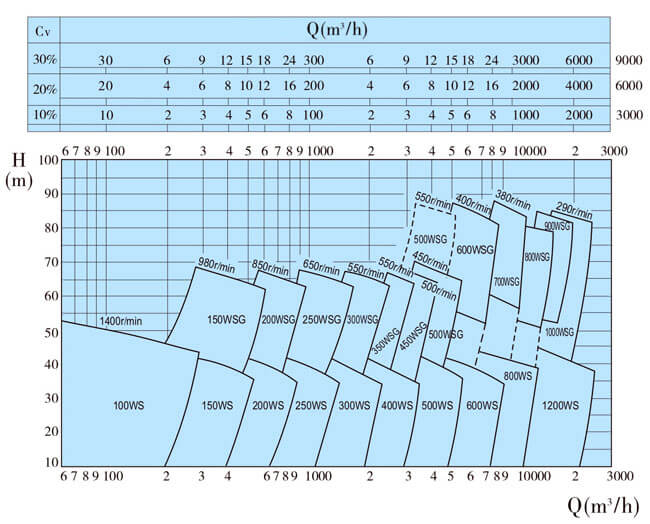

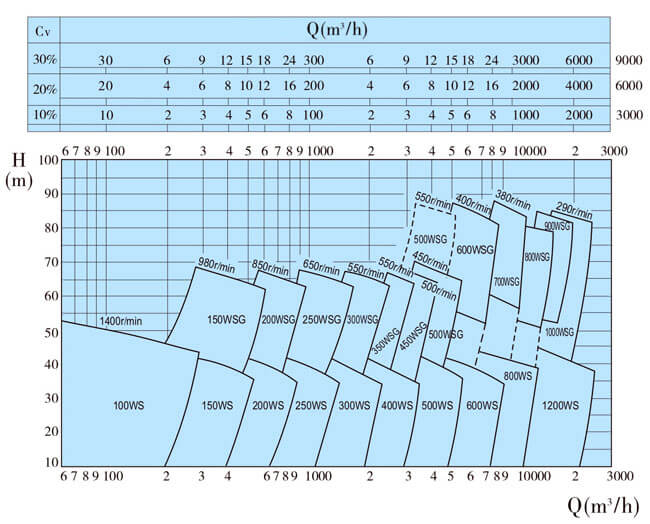

DREDGE PUMP SELECTION CHART

Note: Approximate Performance For Clear Water, To Be Used For Primary Selection Only.

√ Structure suitable for dredgers:

The structure of WN450 type sand dredge pumps are single-casing, single-stage, single-suction, cantilever and horizontal. According to the connection with the gearbox, two structures can be offered: self-carrying bracket and pump-box assembly. The lubrication for the bracket is grease or thin oil.

√ Easy to Disassembly and Installation, Convenient Maintenance:

WN450 sand dredge pump adopts a front-disassembly structure in favor of easy disassembly and maintenance. Also, it is equipped with special disassembly tools for each different part according to each part’s features. The standard trapezoidal quadruple thread is adopted to connect the impeller and shaft, which not only transmits strong torque but also is easy to disassembly.

√ Good Performance on NPSH:

The good NPSH performance of WN450 sand dredge pump ensures the strong suction ability as well as deeper dredging depth and denser dredging concentration.

√ Good Wear-resistant Performance, Long Service Time of Wet Parts:

Wear parts of this kind of dredging pump-impeller, liner and front & back liner plate are adapted anti-wear cast iron alloy whose hardness is more than 58HRC, who has both strong anti-attack feature and higher resistance wear and resistance abrasion features. The hardness of TA31 material that is researched and tested successfully by us can research 70HRC.

√ Reliable Shaft Sealing Without Leakage:

The shaft of WN450 dredging pump uses the mechanical sealing or stuffing sealing or mechanical-stuffing compound sealing.

√ Construction:

• preparation, pumping and recycling of bentonite

• transportation of mud, sand, and gravel

• pumping in depth and special foundations

• moving slurries in civil works

• emptying sludge for tunnel construction

√ Industry:

• pumping and recycling in cement mills and concrete factory

• sand and gravel winning in quarries

• pumping heavy/dirty water in mines(gold, diamonds, coal, copper…)

• extraction of very dense and abrasive liquids in mine (salt, uranium…)

• waste water treatment plant

• cleaning sand filters

• cleaning of sedimentation tanks

• pumping of scales, tar, oil residues, waste, tailings, lime in industry

√ Dredging:

• cleaning and dredging of marinas, harbors, dams, rivers, lakes, irrigation channels

• sand extraction

• marine salvage

• pipes and cables laying systems

• ship unloading

• high depth pumping works