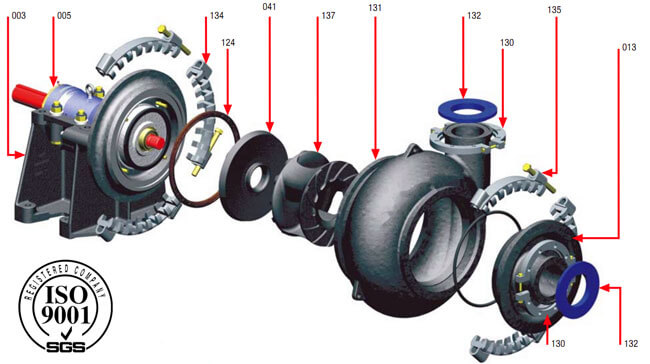

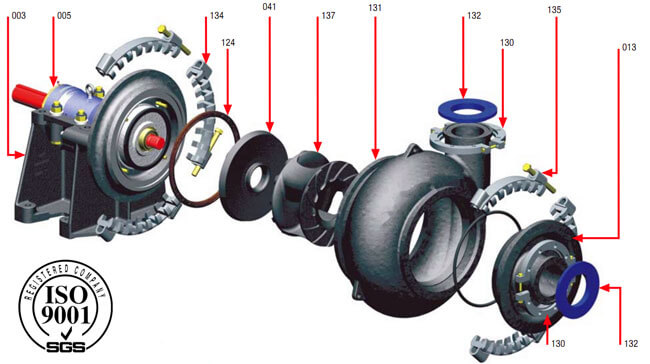

Construction of G Gravel pump

Main Part Number At The Drawing

003:Base 005:Bearing Assembly 132:Intake Joint, Discharge Joint

130:Discharge Flange, Intake Flange 013:Cover Plate 131:Bowl

137:Impeller 041:Back Liner 135:Door Clamp Ring

134: Adapter Plate Clamp Ring 124:Volute Cover Seal

>>>>Matel Pump Parts For Sale

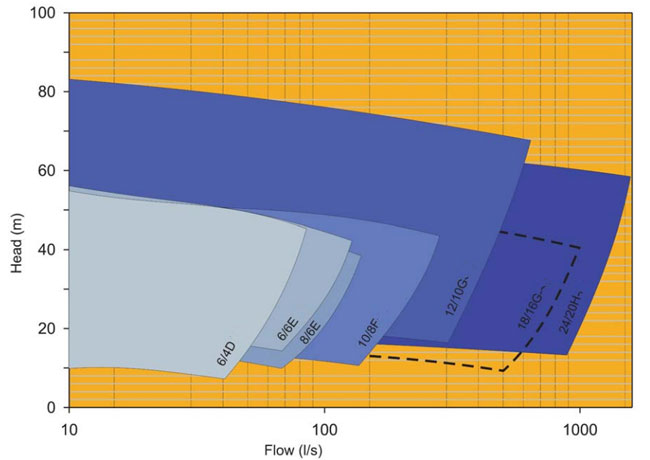

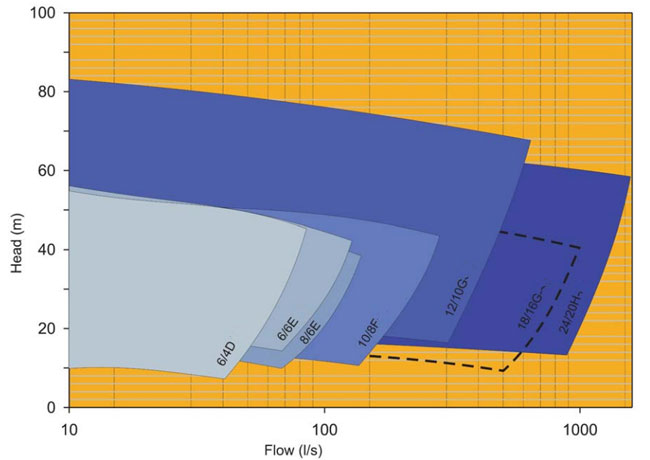

GRAVEL PUMP SELECTION CHART

Note: Approximate Performance For Clear Water, To Be Used For Primary Selection Only.

6x4D-G Sand and Gravel Pump is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life.

G/GH heavy-duty sand & gravel pump design typically caters for high head high volume duties, the sand and gravel pump is best suited to Sand & Gravels, Dredging, Cutter Suction Dredger, Sand Excavation, Coal Washing, Tunnels, Power Plant, Mineral Processing Plants, Higher head cyclone feed or Long distance pipeline duties and Other industries.