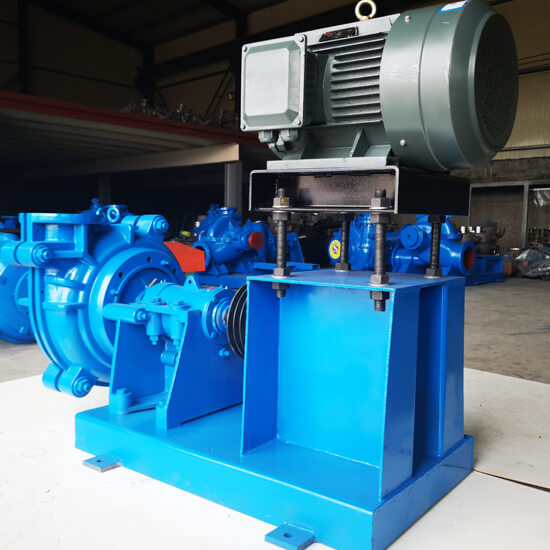

Electric Slurry Pump Rubber Parts

Metal Parts

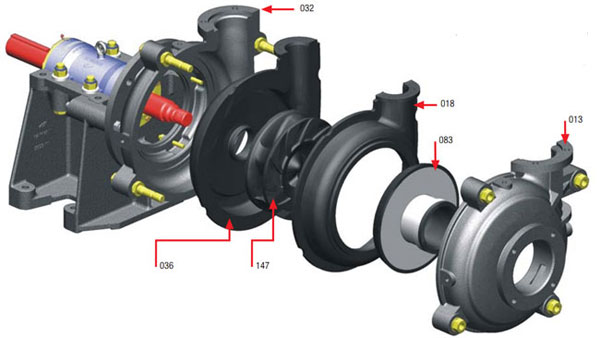

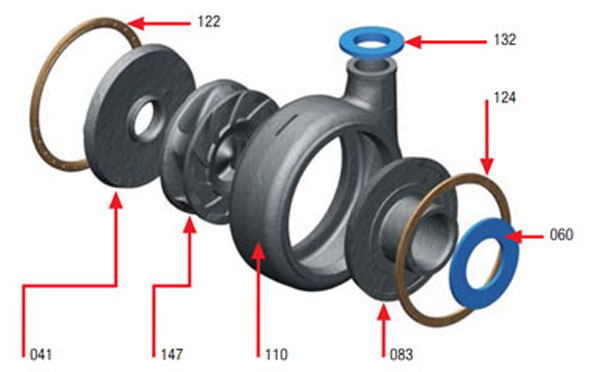

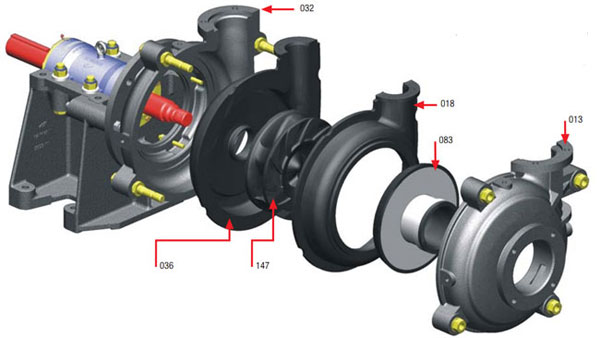

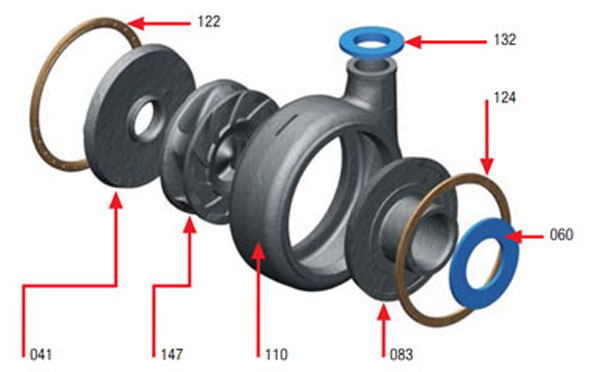

Main Part Number At The Drawing

032:Frame Plate

060: Intake Joint

132:Discharge Joint

083:Throatbush

110:Volute Liner

147: Impeller | 122: Stuffing Box Seal

036: Frame Plate Liner

013:Cover Plate

018:Cover Plate Liner

124: Volute Cover Seal

041: Frame Plate Liner Insert |

>>>> Pump Parts For Sale

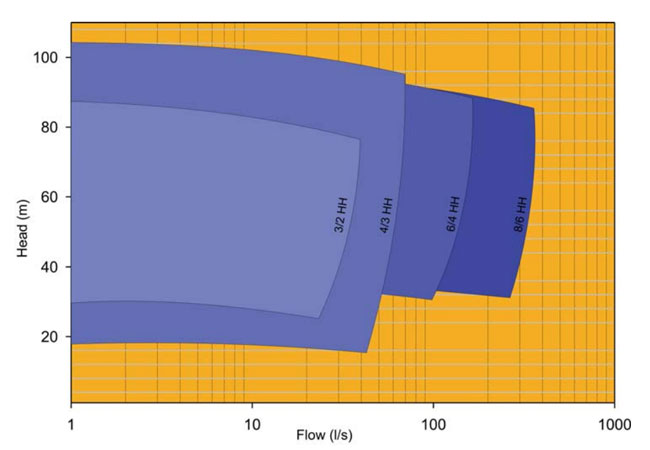

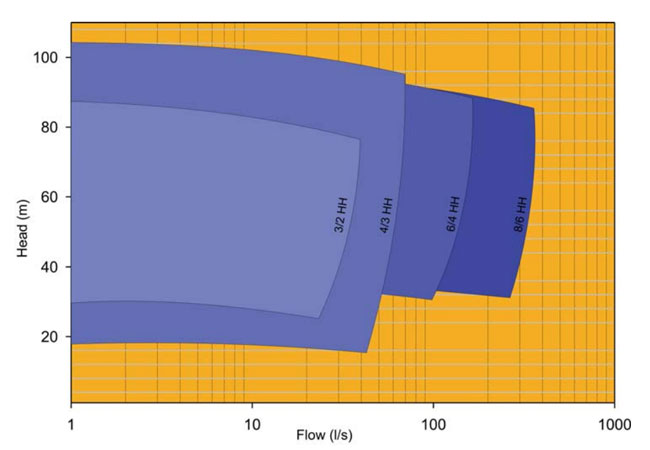

Selection Chart

Note: Approximate performance for clear water,to be used for primary selection only.

1. Ductile iron fully lined casing provides durability, strength and long service life.

2. Multi-stage high pressure operation to 750 psi.

3. Heavy duty construction with through-bolt design provides ease of maintenance and minimal downtime.

4. Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and low operating costs.

5. Large, open internal passages designed to maximize wear life and lower operating costs.

6. Thick elastomer and alloy liners provide superior corrosion resistance and maximum wear life.

7. Full flush gland, low flow, and dry running centrifugal seals reduce flush water usage minimizing electric slurry pump operating costs.

HH high head slurry pumps widely used for wet crushers, SAG mill discharge, ball mill discharge, rod mill discharge, Ni acid slurry, coarse sand, coarse tailings, phosphate matrix, minerals concentrate, heavy media, dredging, bottom/fly ash, lime grinding, oil sands, mineral sands, fine tailings, phosphoric acid, coal, flotation, sugar beets, process chemical, pulp and paper, FGD, waste water etc.