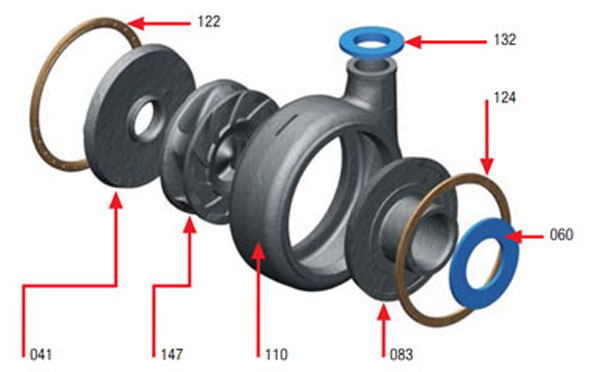

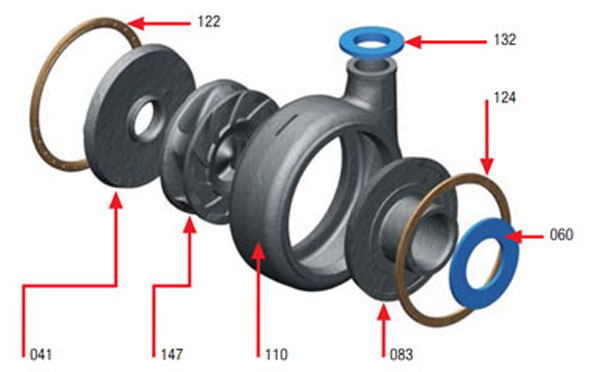

Rubber Parts

Metal Parts

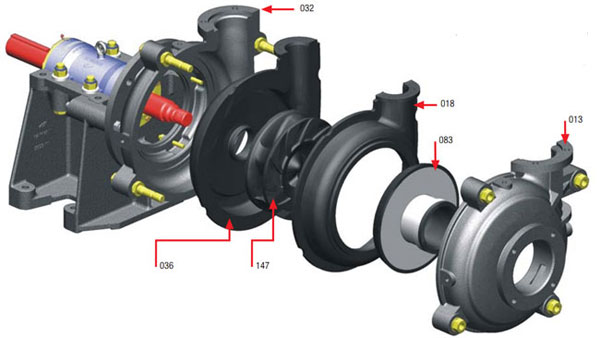

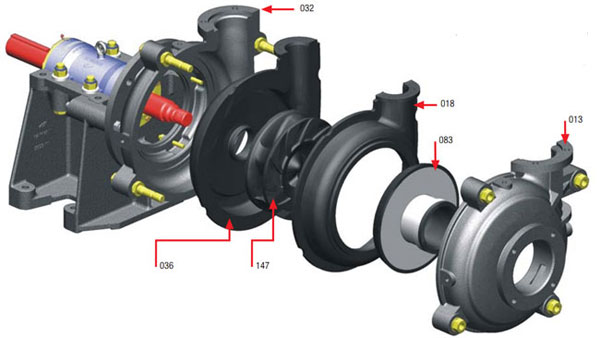

Main Part Number At The Drawing

032:Frame Plate

060: Intake Joint

132:Discharge Joint

083:Throatbush

110:Volute Liner

147: Impeller | 122: Stuffing Box Seal

036: Frame Plate Liner

013:Cover Plate

018:Cover Plate Liner

124: Volute Cover Seal

041: Frame Plate Liner Insert |

>>>> Pump Parts For Sale

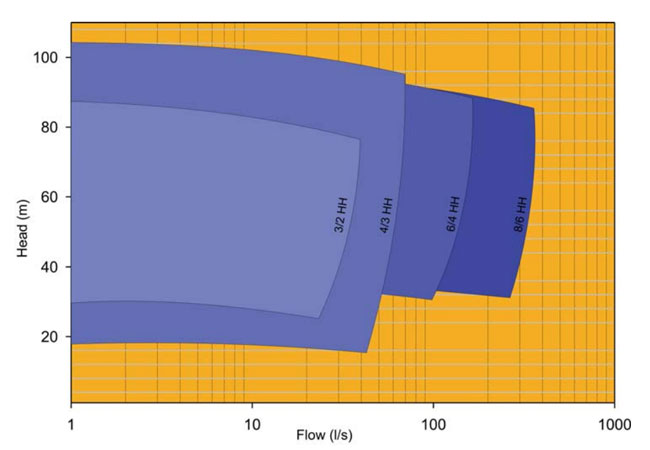

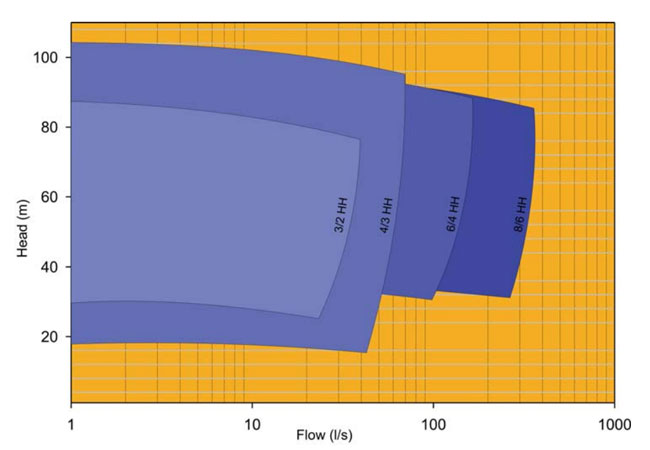

Selection Chart

Note: Approximate performance for clear water,to be used for primary selection only.

1. Ductile iron fully lined casing provides durability, strength and long service life.

2. Multi-stage high pressure operation to 750 psi.

3. Heavy duty construction with through-bolt design provides ease of maintenance and minimal downtime.

4. Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and low operating costs.

5. Large, open internal passages designed to maximize wear life and lower operating costs.

6. Thick elastomer and alloy liners provide superior corrosion resistance and maximum wear life.

7. Full flush gland, low flow, and dry running centrifugal seals reduce flush water usage minimizing pump operating costs.

6x4F-HH High Head Slurry Pump have been developed to handle very high working pressures capable of handling even abrasive slurries with ease. Designed for high performance, high energy efficiency and long wear life, the high head slurry pumps serve a variety of slurry transportation applications, Shares have proven unique design features with the AH series slurry pump range. High-pressure design constructed as horizontal, end suction centrifugal pumps to maximise wear resistance and simplify maintenance. Made with abrasion resistant white irons, ductile irons and special alloys to match duty requirements. Other wear liner materials such as urethane are also available. In a word, slurry transport using centrifugal pumps.

6x4F-HH High Head Slurry Pumps Applications:

Mining – Open Pit / Underground

Slime Settling Sumps

Ore Reclaim Conveyor Sumps

Ball Mill Sumps

Mine Dewatering Clarifier Underflow

Paste Fill Operations

Concentrate Transfer

Smelter Wash Down Sumps

Slurry Transfer

Settling/Collection Ponds

Oil Refining & Recovery

Skimmer Oil Sumps

API Lift Station High Solids Sumps

Coker Sumps

Sand and Bitumen Sludge Extraction Plant Emergency Dump Pond

Power Generation

Scrubber Sludge

Material Handling Sumps

Bottom Ash and Fly Ash Sumps

Clarifier Ash Removal

Coal Galley Wash Down Sumps

Main Plant Collection Sump

Cooling Tower Overflow Sumps

Neutralization Sumps

Polisher Sumps FGD Sumps

Spent Lime Sumps

Condenser Sumps

Site Retention Ponds

Low-Level Waste/Boiler Blowdown Sumps

Caustic Sumps

River Dredging

Plant Water Pumps

Steel Mills & Heavy Industries

Mills Scale Pits

Blast Furnace Slag Pits

Clarifier Underflow

Ethanol/Grain Processing

Collection Sumps by Fiber Scrubber

Feed Loadout

Boiler Pad

Receiving Bay and Storage Areas

Pulp & Paper

Paper Waste Collection Sump

U-Drain Sumps

Wood Yard Sumps

Clean Up Sumps

Water Treatment and Wastewater & Sewage

Activated Sludge

Dewater Holding Tank

Sludge Transfer

Chemical

Caustic and Acidic Sumps

Waste Sludge Handling

Tank Clean Out

Clean Up Sumps

Waste Collection Ponds

Thickener Clean Out

Barge Unloading

Food Processing

Receiving Collection Sumps Sugar: Lift Stations

Anaerobic Clarifiers

Aerobic Clarifiers

Ash Ponds

Rock Catcher Sumps

Beet Wash Down

Flume Sumps

Potato Plants: Plant Collection

Wash Down Sumps