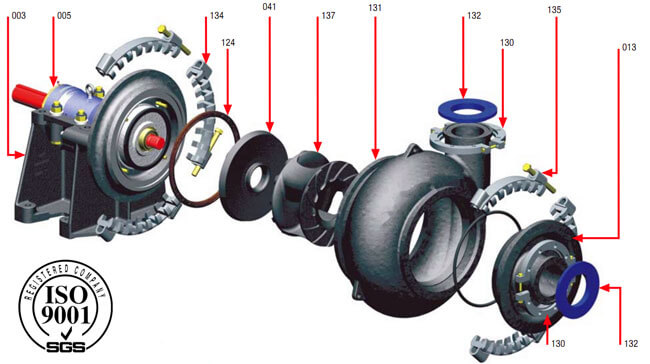

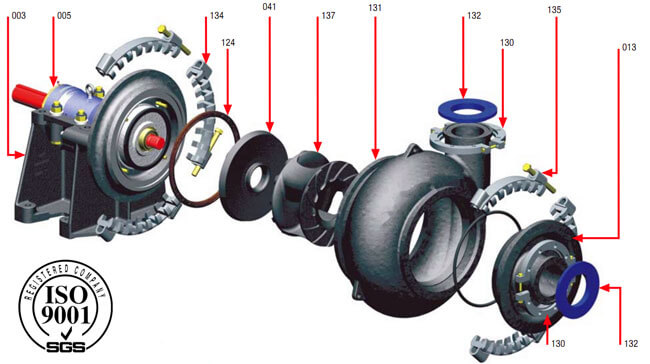

Construction of G Gravel pump

Main Part Number At The Drawing

003:Base 005:Bearing Assembly 132:Intake Joint, Discharge Joint

130:Discharge Flange, Intake Flange 013:Cover Plate 131:Bowl

137:Impeller 041:Back Liner 135:Door Clamp Ring

134: Adapter Plate Clamp Ring 124:Volute Cover Seal

>>>>Matel Pump Parts For Sale

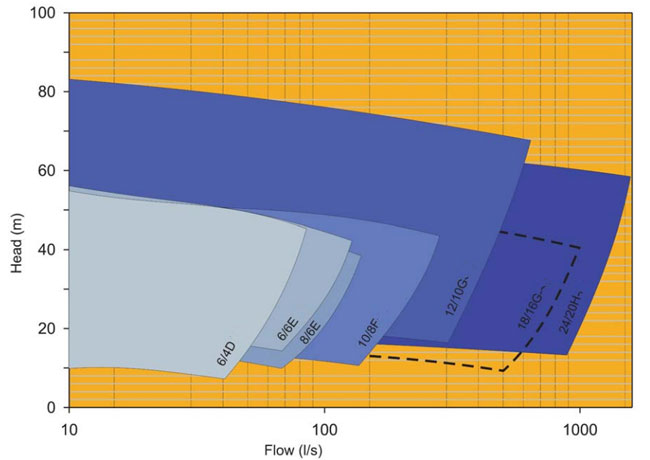

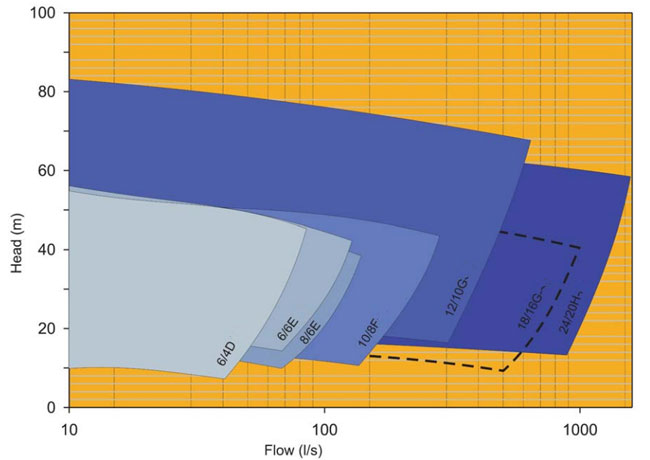

GRAVEL PUMP SELECTION CHART

Note: Approximate Performance For Clear Water, To Be Used For Primary Selection Only.

√ The unique segmented clamp ring on larger size units and solid on smaller pumps, facilitates casing rotation to any angle, reducing the need for costly high wearing bends. Minimal maintenance is required.

√ Impeller expulsion vanes reduce gland pressure and intrusion of high concentrations of solids in the gland area. Efficiency is maintained by minimising suction side recirculation.

√ Specially designed and shaped impeller vanes allow the handling of extraordinarily large particles. The unique casing design and sealing vanes prevent abrasive solids intrusion at the sealing faces.

√ The large, robust casing has been designed to reduce internal velocities resulting in minimum efficiency loss and improved casing wear life. The casing is made up of three components to reduce maintenance time and costs associated with a onepiece design. (Except the 6/4 DG which has two components)

√ Tobee heavy-duty grease lubricated taper roller bearing assemblies are fitted as standard. A rigid large diameter shaft with reduced overhang minimises deflection and vibration under all conditions ensuring trouble free operation. Unusually high service factors enable the assembly to carry all radial and axial thrusts.

√ A unique “-10” (dash 10) end cover assembly comprising of V-seals, double piston rings and an external flinger with grease lubricated labyrinths are standard with all Walker pumps

G/GH heavy-duty sand & gravel pump design typically caters for high head high volume duties, The Gravel pumps are best suited to Sand & Gravels, Dredging, Cutter Suction Dredger, Sand Excavation, Coal Washing, Tunnels, Power Plant, Mineral Processing Plants, Higher head cyclone feed or Long distance pipeline duties and Other industries.